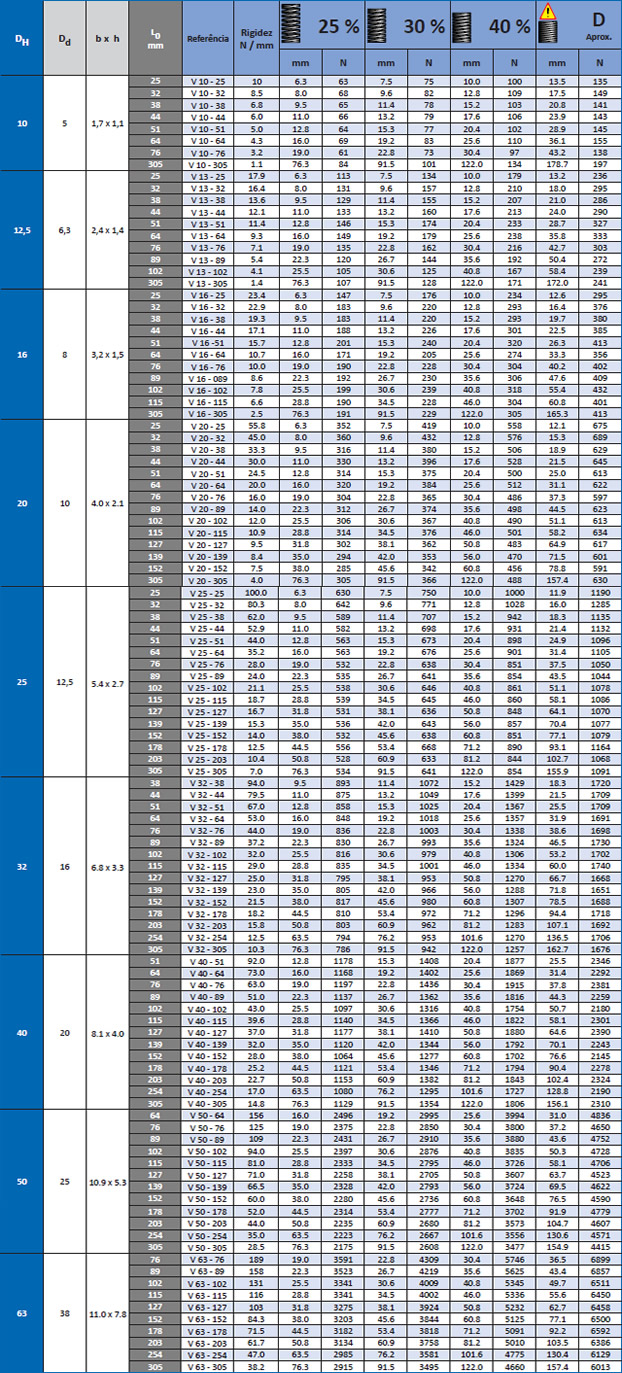

LIGHT LOAD SPRINGS

Indicated for light loads.

Green spring, series B has the rectangular section, with 9 options of diameters and lengths ranging from 25 to 305 mm (ISO 10243).

More Information

Especificações Mola:

| MATERIAL | |

|---|---|

| Profile Type: | Spring TV-Round |

| Maximum Deflection: | |

| Diameter Tolerances |  |

| Length Tolerance | |

| Tolerance Stiffness |

Technical and manufacturing characteristics

The constant development together with strict quality assurance procedures in accordance with ISO 9001, promotes SS Springs high levels of durability, dimensional accuracy and reliability. The excellence of these products is proven by the growing number of customers who choose and specify SS springs into your tools.

Below is the essential aspects that ensure the superiority of SS Springs:

- The use of specially developed alloys for springs SS;

- The use of special profiles to improve the properties of steel

- The use of special equipment to manufacture the springs

- The use of unique heat treatment;

- Maximum attention to ensure perfect closing of the links and ensure a great perpendicular alignment

- Special pre-treatment and powder coating to improve the protection, preservation and identification of springs

- Extensive inspections during the production process and final inspection to ensure maximum dimensional accuracy and uniformity;

Instructions and special care

To optimize the use of springs and to obtain a useful life within the normal standards of use, it should be noted the following have any suggestion:

- Select carefully the spring in the design stage;

- Use an internal guide and a hole to position and guide, this is essential to have the length of free spring;

- Ensure that squareness of the springs to withstand compression surfaces;

- Apply a minimum preload of 5% of the free length;

- Never compress Springs beyond the maximum deflection (pre-load and working stroke) specified in the last column of the catalog;

- Do not exceed a temperature of 250° C. Till 120° C does not occur significantly reduced load, beyond this temperature an average loss of 1% for every 40° C should be considered;

|

|

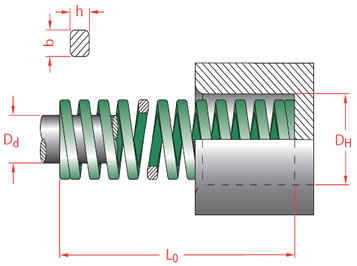

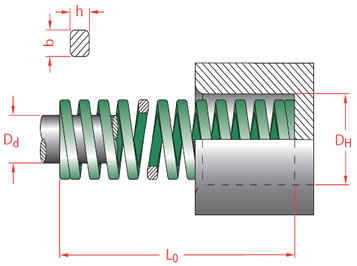

Subtitle: DH= Diameter of hole |

How to request quotes and products

Specify the item with the prefix (V), DH diameter and length L0.

Note: 1N=0,102 KG(Força)

See the table below with the measures:

|

|

Subtitle: DH= Diameter of hole |

How to request quotes and products

Specify the item with the prefix (V), DH diameter and length L0.

Note: 1N=0,102 KG(Força)

See the table below with the measures:

To request the spring quote, specify:

Spring series: (color) + diameter of hole (Dh) + free length of load (Lo)

Note: 1N=0,102 KG(Força)

If you need help to determine the required spring type in your project, please contact Polimold, our staff is ready to guide you on the best model for the correct operation of your tool.